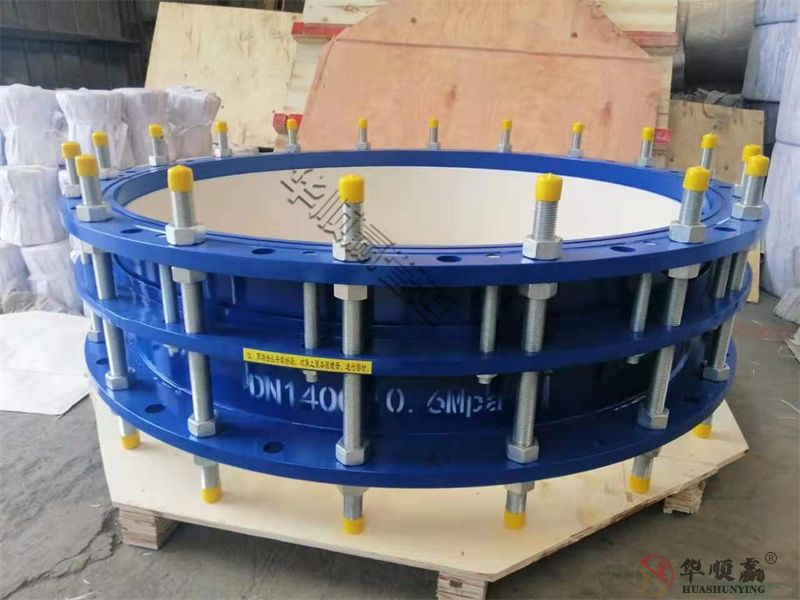

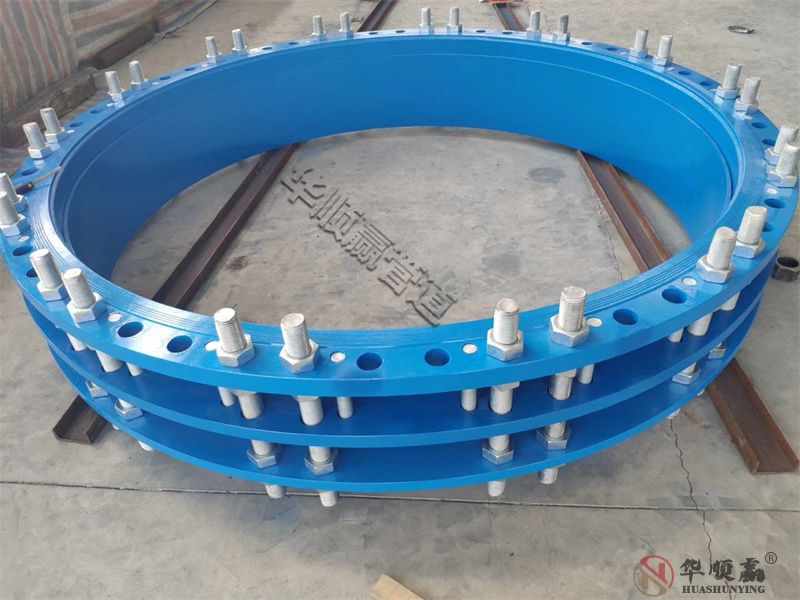

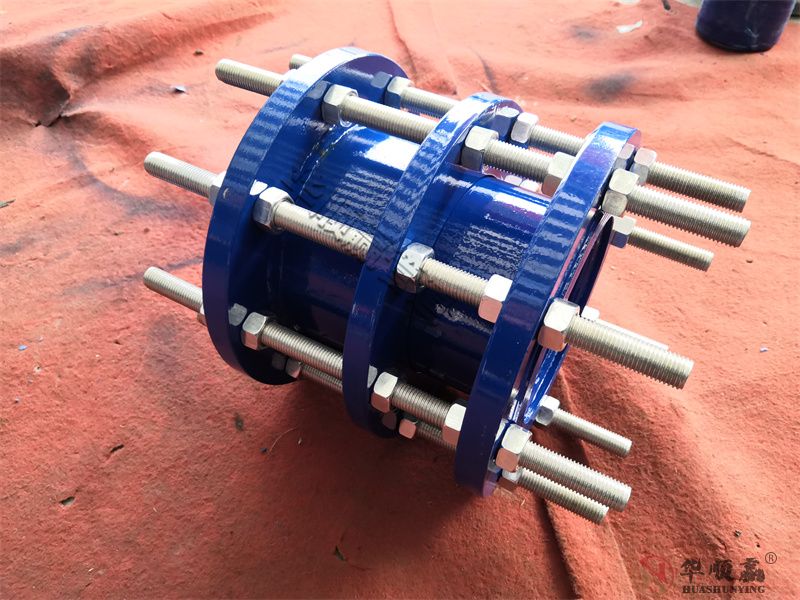

C2F (VSSJAF) type double flange dismantling joint is composed of flange loose sleeve expansion joint, short pipe flange, force transmission screw and other components, which can reduce the pressure thrust (blind plate force) of the connected parts and compensate for pipeline installation error. The double flange power transmission connection is mainly used for the loose sleeve connection of accessories such as pumps and valves. C2F (VSSJAF) type double flange power transmission joint is suitable for conveying seawater, fresh water, hot and cold water, drinking water, domestic sewage, crude oil, fuel oil, lubricating oil, refined oil, air, gas, and steam with a temperature not higher than 250 degrees and granular powder and other media.

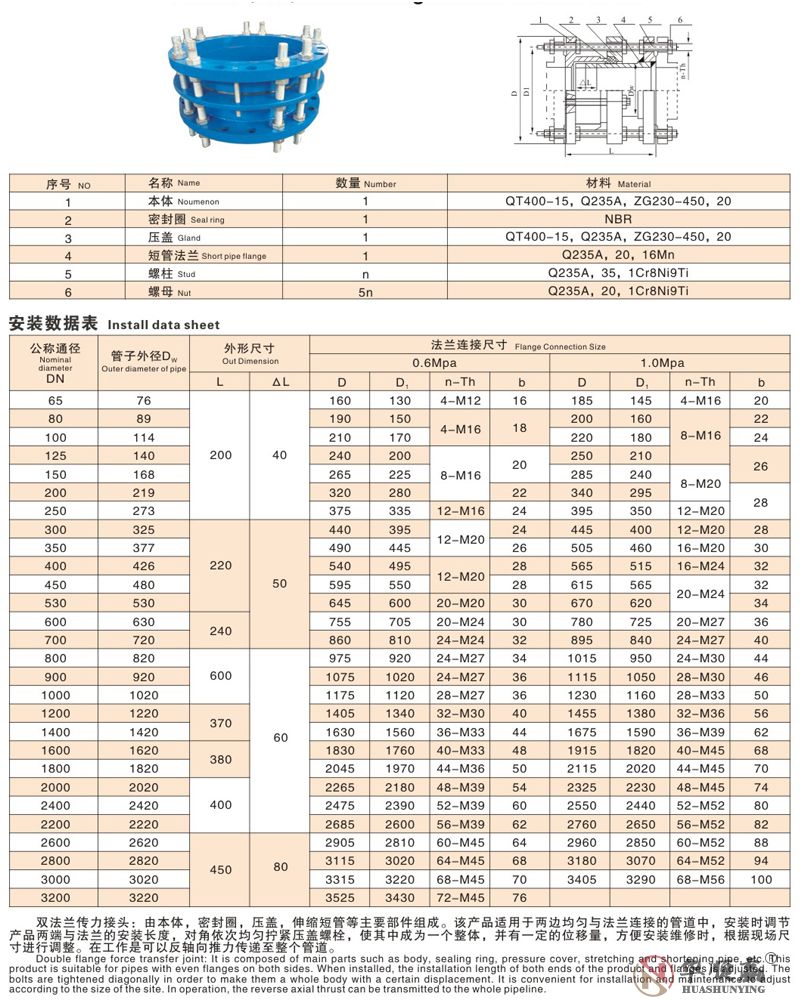

Data sheet:

What should be paid attention to when working with double flange power transmission joints

When the double flange power transmission joint is welded, the sealing effect of the pipeline is the welding heat affected zone, which refers to the area where the metallographic structure and mechanical properties of the metal near the weld are changed due to the action of welding heat. Due to the different heating conditions of each point near the weld, the heat-affected zone can be divided into fusion zone and overheating zone, normalizing zone and partial phase transition zone, etc.

Due to the different distances from each point to the center of the weld, the high temperature of the weld is also different. And because heat conduction takes a certain amount of time, each point reaches the high temperature point at different times, but in general, during the welding process, the formation of the weld is a metallurgical process, and the metal in the area near the weld is equivalent to receiving it. A heat treatment of different specifications will inevitably produce changes in the corresponding structure and properties.

1. Before installing the double flange power transmission expansion joint, it is necessary to check the type and size of the power transmission joint to see if the power transmission joint is compatible with the current pipeline or valve;

2. Determine the flow direction of the medium. The force transmission joint also has certain requirements for the direction during installation. There are so-called inlets and outlets. If the installation is wrong, the force transmission joint will be damaged;

3. It must be ensured that the installation is carried out within the working maximum limit range of the power transmission joint. Although the power transmission joint has a certain displacement effect on the pipeline, its displacement is very small, and its displacement cannot be exceeded during installation;

4. During installation, the integrity of the power transmission joint must be ensured, and there should be no internal or external mechanical damage;

5. The rubber sealing device inside the power transmission joint must be complete. During the installation process, the rubber sealing device is very important. If necessary, a rubber ring can be added for sealing;

6. After the pipeline and the power transmission joint are installed, the limit device must be adjusted to a suitable position to ensure the normal use of the limit device of the power transmission joint;

7. During formal work, the water inlet pressure should be increased constantly, avoid directly pressurizing to the limit pressure, and prevent the bursting of the force transmission joint due to excessive pressure.

Tel:+86-0371-61070766

Fax:+86-0371-61070766

Phone:+8615136203167

Email:info@sypipeline.com

Add:Pipeline Equipment Park, Xicun Town, Gongyi City, Henan Province, China